Is epoxy resin waterproof? Once fully cured, yes—it creates a solid, non-porous barrier that blocks out water and moisture.

This is one of the main reasons epoxy is widely used as a sealant across various projects, from countertops to outdoor furniture.

After it finishes bonding and hardening, epoxy forms a tough, durable layer that resists water, other liquids, and even humid air.

In this article, we’ll dive into how epoxy resin holds up in wet environments and how you can ensure your project stays sealed for the long haul.

Is Epoxy Resin Waterproof?

Once fully cured, epoxy resin is considered waterproof. It forms a hard, durable, and moisture-resistant surface that can effectively protect against water.

This makes it a popular choice for sealing surfaces, coating countertops, and use in craft or marine projects.

However, it's important to understand the distinction between water-resistant and waterproof.

Water-Resistant vs. Waterproof

- Water-Resistant: Cured epoxy resin effectively repels water, making it suitable for areas exposed to occasional splashes or brief water contact, such as kitchen counters, bathroom surfaces, or art projects.

- Waterproof: While epoxy offers a strong barrier, it is not 100% waterproof in the strictest sense. Continuous or long-term water exposure, such as full submersion or use in underwater environments, can eventually lead to water infiltration, especially if not applied properly or if the surface becomes damaged.

Cure epoxy resin provides excellent water resistance for everyday applications. However, for long-term submersion or heavy-duty marine use, additional waterproofing measures or specialized marine-grade epoxies may be required.

Factors Influencing Epoxy Resin's Water Resistance

The ability of epoxy resin to resist water is affected by various factors including the quality of the formulation, application techniques, and the curing process. Each factor plays a crucial role in determining how well the epoxy can defend against moisture.

1. Quality of Formulation

Different epoxy formulations offer varying levels of resistance to water intrusion. Some formulations are explicitly engineered for superior water resistance, incorporating additives that enhance barrier properties.

When selecting an epoxy resin, consider its intended use. For example, marine-grade epoxy is designed to withstand prolonged water exposure, making it ideal for boat repairs.

- Additives: Some epoxies contain fillers that can improve water resistance.

- Composition: Look for formulations with chemical compositions that enhance durability and moisture barriers.

Choosing the proper formulation is critical to achieving strong water-resistant properties.

2. Application Techniques

Proper application techniques are essential to ensure epoxy resin performs as expected. Surface preparation is a key step, as any dirt or grease can compromise adhesion. Cleaning and sanding the surface helps create a strong bond.

- Mixing ratios: It is important to adhere to the specified resin and hardener ratios. Incorrect ratios can lead to incomplete curing and reduced water resistance.

- Application methods: Using techniques like rolling or brushing ensures even coverage, minimizing potential weak spots.

Following these guidelines helps achieve the best protective seal against water.

3. Epoxy Resin Curing Process

The curing process is crucial to maximizing the water-resistant properties of epoxy resin. It involves a chemical reaction that solidifies the material, creating a tight barrier.

- Time: Allow sufficient curing time as rushed processes may leave the epoxy soft or sticky, reducing its effectiveness.

- Conditions: Maintain optimal temperature and humidity levels during curing. Extreme conditions can affect the resin's ability to cure fully.

Completing the curing process ensures the epoxy reaches its full potential in resisting water.

Tips on Avoiding the Humidity Problem

Epoxy resin is sensitive to moisture, which can cause curing problems. Controlling humidity levels can ensure a smooth application and curing process. Here are some practical strategies to keep humidity at bay.

1. Use a Dehumidifier

Place a dehumidifier in your workspace. This device will help control moisture levels. Reducing humidity creates a stable environment for the epoxy to cure properly.

Run the dehumidifier for a few hours before starting your project. This preemptive step ensures the air is dry enough for the epoxy.

While working with epoxy, keep the dehumidifier on. This maintains low humidity throughout the application. It is important to choose the right size dehumidifier for your space.

A more powerful unit may be needed to manage moisture effectively in a larger room. To keep the dehumidifier functioning properly, regularly check and empty its water reservoir.

2. Work in a Climate-Controlled Environment

Consider working in an environment where temperature and humidity can be controlled. Using air conditioning can help maintain a stable temperature and reduce humidity.

This controlled setting provides ideal conditions for the epoxy to set effectively.

Set your HVAC system to regulate climate as needed. Consistency in temperature and humidity levels is key. This control not only aids in proper epoxy curing but also reduces other potential moisture-related issues.

If installing a permanent system is not feasible, portable air conditioners or space heaters can help in smaller areas, offering similar climate control benefits.

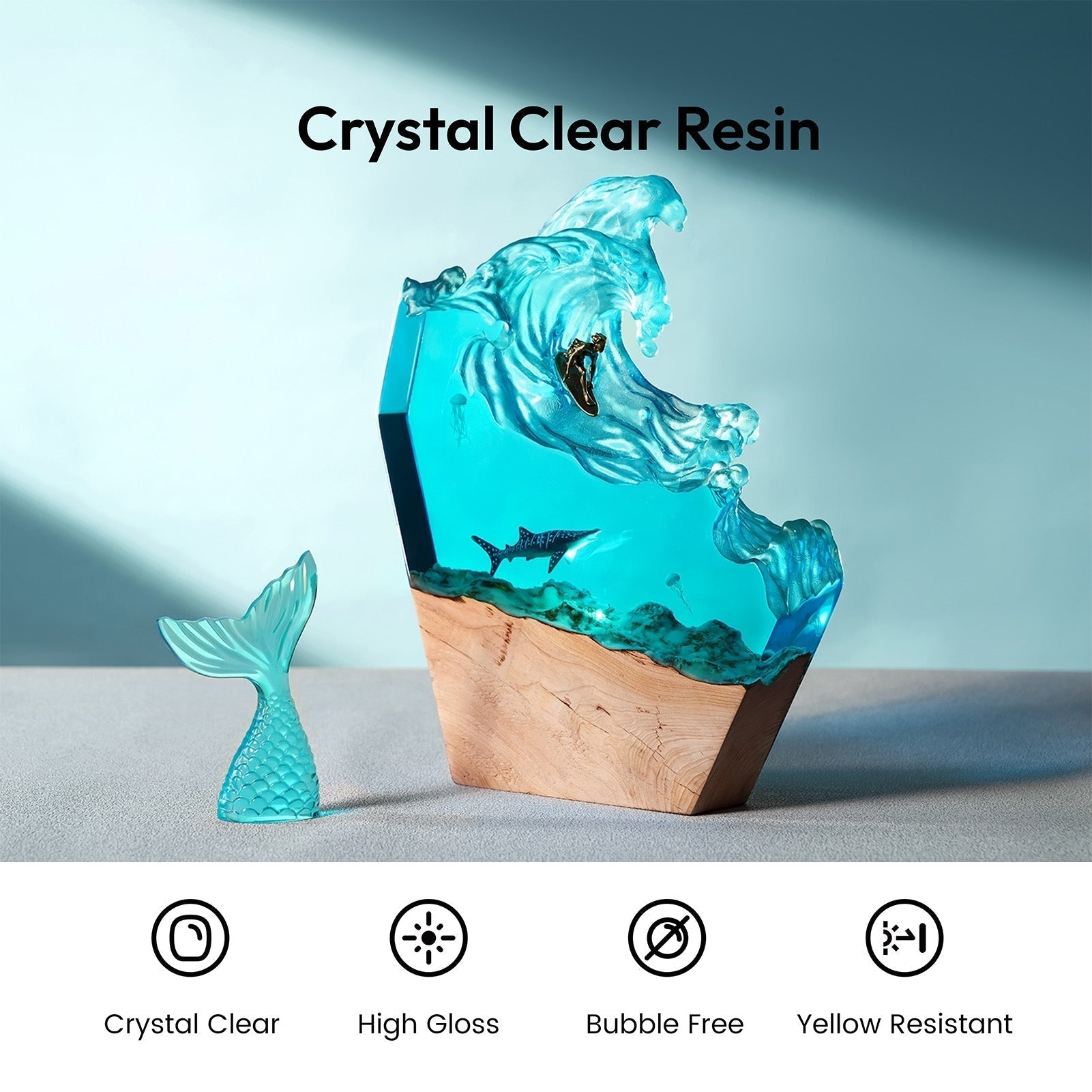

Choose a Premium Epoxy for Your Resin Projects

The quality of your epoxy can make or break your project. Whether you're creating jewelry, art, or tabletops, using a premium epoxy resin ensures better results, easier application, and a longer-lasting finish.

Here’s what to look for when choosing an epoxy:

- Crystal Clear Finish: Look for resins that cure to a high-gloss, glass-like finish. A truly clear formula enhances your project’s colors and details.

- Bubble-Free Formula: A good epoxy should self-level and include anti-bubble technology for a smooth, professional surface—no need for excessive heat-gun work.

- Fast Cure Time: Products like Resiners® Crystal Clear Epoxy Resin offer an 8-hour cure time, letting you enjoy your finished piece sooner.

- Low Odor & VOC-Free: Choose an epoxy with low fumes and no harmful VOCs. It’s safer to use indoors and more pleasant to work with.

- Non-Yellowing Protection: UV-resistant formulas help keep your resin looking fresh and precise over time without discoloration.

- Easy to Pour, Less Mess: Modern formulas are designed for better control during pouring, helping reduce spills and improve precision.

- Versatile Applications: A high-quality epoxy should be suitable for multiple project types, including jewelry, art, coasters, tabletops, and more.

Selecting an epoxy with these features will give you a smoother experience and a beautiful, lasting result.

If you're looking for a trusted option, Resiners® Crystal Clear Epoxy Resin checks all the boxes.

Check Out Related Products:

Resiners® AirLess Resin Bubble Remover Machine

Achieve crystal-clear results in just 5–9 minutes with the Resiners® AirLess Bubble Remover. This efficient machine eliminates bubbles from your resin quickly and quietly, thanks to a built-in noise reduction design that keeps sound levels under 56 dB—perfect for home or studio use.

|

|

Resiners® Upgraded Dual-Head Resin Mixer

The Resiners® Upgraded Dual-Head Resin Mixer offers hands-free operation with stepless speed control, cutting mixing time and reducing air bubbles compared to traditional hand mixing.

|

|

Resiners® Patented Cure Air Resin Curing Machine

Resiners Cure Air now features an upgraded tray with increased size, height, and stiffness. Measuring 11.8 x 8.5 x 1.8 inches, it fits molds up to 1.8" tall. A reinforced center support keeps the tray level and prevents warping, even with heavy molds.

|

Practical Applications of Epoxy Resin in Moist Environments

Epoxy resin is often used in moist environments because of its water-resistant properties. Whether it's for boats, floors, or artwork, epoxy can provide a sturdy barrier against moisture.

Marine Industry: Epoxy resin is popular in boat building and repairs. It helps seal and protect watercraft from water intrusion. Proper application is important to ensure its good performance.

Flooring Solutions: Epoxy flooring is a great choice for areas like basements and garages. These areas are often exposed to moisture. Epoxy creates a seamless, water-resistant surface. This makes it easier to clean and maintain compared to other flooring options.

Art and Crafts: In the world of art and crafts, epoxy resin is used to create water-resistant pieces such as jewelry and artwork. While epoxy can handle some moisture, it's important to note that long-term water exposure might still affect the material.

- Marine applications: Boat building, repairs

- Flooring: Basements, garages

- Art and crafts: Jewelry, decorative art

Each application benefits from epoxy's ability to keep moisture out, but for best results, always consider the level of exposure to water.

Conclusion

Once fully cured, epoxy resin is waterproof, making it a reliable choice for sealing surfaces and creating durable outdoor art.

However, proper mixing, application, and curing are key to ensuring its water-resistant properties hold up over time.

Whether you're working on countertops, jewelry, or functional crafts, understanding how epoxy behaves with moisture is essential.

Consistent curing conditions matter to get the best results in every project.

Explore the Resin Curing Machine from Resiners® for precise, hassle-free curing that helps your epoxy resin reach its full potential—every time you create.

Frequently Asked Questions

Epoxy resin is widely used for its waterproof qualities, durability, and clear finish. You may wonder about its specific properties, especially when exposed to different conditions like saltwater or sunlight.

How Long Before Epoxy is Waterproof?

Epoxy typically becomes waterproof once it has fully cured, which usually takes about 24 to 72 hours depending on the specific product and environmental conditions. It's important to follow the manufacturer's instructions for curing times to ensure the epoxy achieves its full waterproof properties. Premature exposure to water can interfere with the curing process and affect the epoxy's performance.

How Does Saltwater Affect Epoxy Resin?

Saltwater can be harsh on many materials, but fully cured epoxy resin is highly resistant to saltwater. It forms a durable, protective barrier that can withstand the corrosive effects of salt. This makes epoxy resin an excellent choice for marine applications, such as boat repairs and coatings.

Is Epoxy Resin Safe for Aquariums?

Yes, epoxy resin is safe for aquariums once it has fully cured. It creates a strong, non-toxic seal that won't leach harmful chemicals into the water. Always ensure the epoxy is completely cured before introducing it to an aquarium environment to protect the health of aquatic life.

Does Epoxy Resin Yellow Over Time with Water Exposure?

Some epoxy resins can yellow over time, especially with prolonged UV light and water exposure. However, many high-quality epoxy resins are formulated with UV inhibitors to resist yellowing. Choose a UV-resistant epoxy to minimize yellowing and avoid placing the epoxy-coated items in direct sunlight.

Does Epoxy Get Slippery When Wet?

Yes, epoxy can become slippery when wet, which can pose a safety hazard in certain applications. To reduce slipperiness, you can add non-slip additives to the epoxy during the application process. These additives create a textured surface that provides better traction when the epoxy is wet.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.