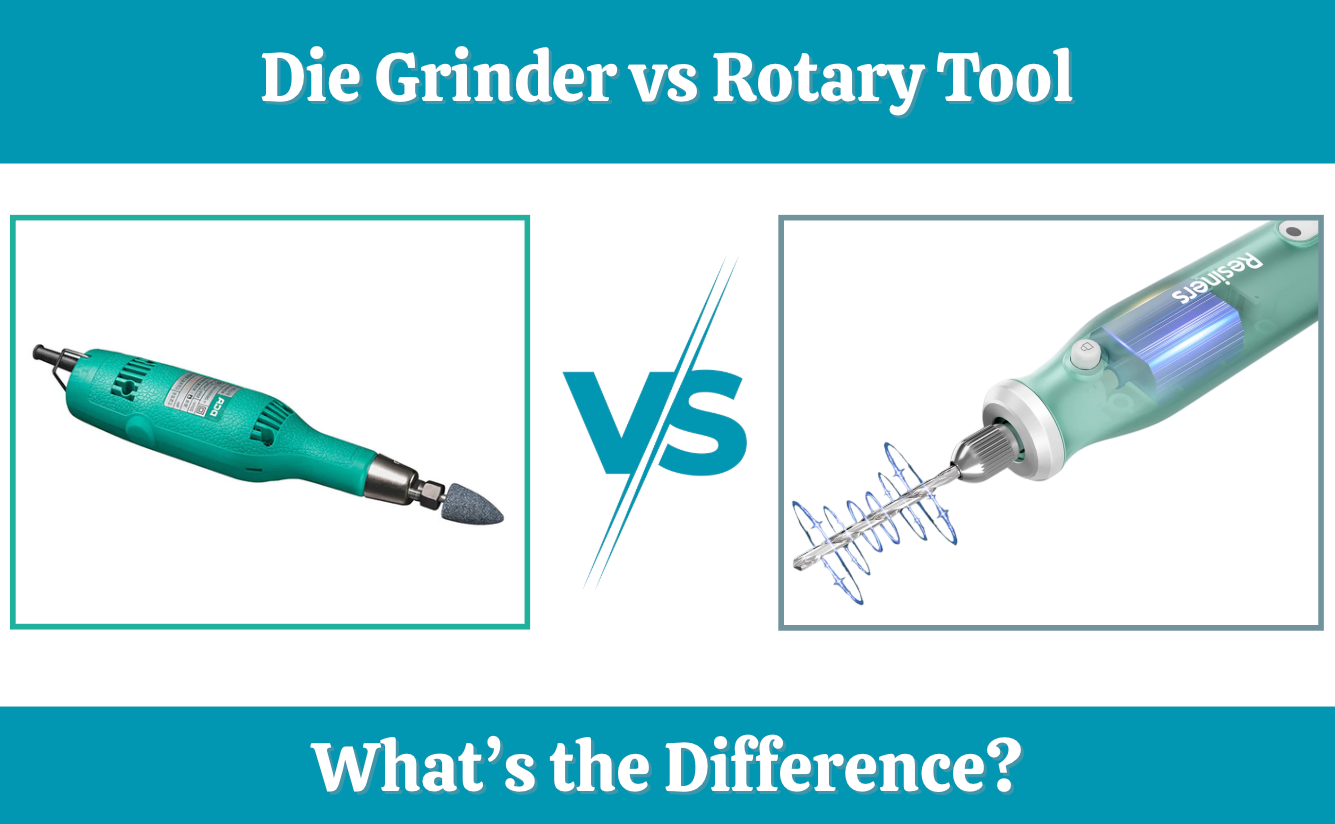

If you are into DIY projects or professional work with tools, you may have come across the terms' die grinder' and 'rotary tool'. At first glance, they look similar. Both are handheld tools with spinning heads that accept various attachments.

However, upon closer examination, it becomes apparent that they differ significantly in terms of power, size, and purpose. Knowing the difference will help you buy the right tool for your needs and avoid frustration.

In this guide, we will explain what sets a die grinder apart from a rotary tool in a way that is simple and easy to understand.

Quick Takeaways:

- Die grinders are bigger, stronger, and designed for heavy-duty jobs like grinding, cutting, and smoothing tough materials such as steel and metal.

- Rotary tools are smaller, lighter, and designed for precision tasks such as engraving, crafting, and polishing delicate materials.

- A die grinder typically utilizes compressed air or large electric motors, featuring a ¼-inch collet.

- A rotary tool typically operates on electricity, often cordless, and features a ⅛-inch collet.

- Die grinders are common in workshops and auto shops. Rotary tools are loved by hobbyists, resin artists, and makers.

- One tool emphasizes raw strength, while the other focuses on finesse and flexibility.

You May Want To Shop

|

|

Unleash your creativity with the Resiners® Cordless Rotary Tool Kit.

This kit delivers the precision and versatility demanded by resin artists and DIY makers for elevating crafts and projects. ⭐⭐⭐ Shop now to power your next creation! ⭐⭐⭐

|

What Is a Die Grinder?

A die grinder is a powerful handheld tool used in industries, garages, and workshops. It gets its name because it was originally made for grinding dies or molds in tool-and-die making.

Key Characteristics of a Die Grinder

- Size: Larger and heavier than rotary tools.

- Power source: Often pneumatic (air-powered) but also made in corded electric models. Pneumatic ones are most common in professional shops.

- Collet size: Standard ¼ inch collet which holds larger bits.

- Torque: High torque to cut, grind, and sand metal quickly.

- RPM: Lower RPM than rotary tools, but packs more torque.

Uses of a Die Grinder

- Smoothing rough welds in auto body or fabrication work.

- Grinding away rust from steel surfaces.

- Cutting bolts or shaping hard materials.

- Deburring sharp edges off aluminum, copper, or metal pipes.

- Using sanding discs or burr bits for heavy-duty shaping.

Simply put, a die grinder is a workhorse tool built for professional-level, power-heavy jobs.

📌Also Read: Is UV Resin Toxic? Safety Guide for Artists and Crafters

What Is a Rotary Tool?

A rotary tool is a smaller handheld tool equipped with a high-speed motor, usually electric. The most famous brand people think of is Dremel, but many other rotary tool brands exist.

Key Characteristics of a Rotary Tool

- Size: Compact and lightweight, easy for one-hand use.

- Power source: Almost always electric, with corded and cordless options.

- Collet size: Standard ⅛ inch collet for smaller bits.

- Torque: Lower torque but extremely high RPM.

- Ease of use: Simple for beginners, widely available in hardware stores.

Uses of a Rotary Tool

- Polishing jewelry and metals.

- Cutting plastic, resin, wood, or small items.

- Engraving custom designs in wood, glass, or resin artwork.

- Drilling small holes with micro bits.

- Sanding small areas in crafts or fine woodworking.

- Sharpening blades with small cutting wheels.

Rotary tools shine when you want precision and flexibility rather than brute power.

📌Also Read: 7 Best Polishing Compound for Epoxy Resin Projects

Die Grinder vs Rotary Tool: The Key Differences

Size and Power

- Die Grinder: Larger design, more weight, more horsepower. Best for mechanical and industrial jobs.

- Rotary Tool: Small, compact, and better for hobbyists and light detail work.

Speed (RPM) and Torque

- Die Grinder: Typically lower RPM but high torque, making it great for grinding hard metals.

- Rotary Tool: Ultra-high RPM (some reach 30,000 RPM) but lower torque, best for delicate jobs.

Collet and Attachments

- Die Grinder: Uses ¼ inch collets. Allows large cutting wheels, burrs, or grinding stones.

- Rotary Tool: Uses ⅛ inch collets. Meant for tiny bits, sanding drums, polishing pads, and engraving tips.

Power Source

- Die Grinder: Usually pneumatic, requiring an air compressor. Electrical versions exist but are bulkier.

- Rotary Tool: Runs on electricity, often convenient cordless designs for at-home use.

Applications

- Die Grinder: Auto shops, construction, industrial fabrication.

- Rotary Tool: Crafts, resin art, jewelry work, small DIY tasks.

Ease of Use

- Die Grinder: Heavier and louder, requires experience to control safely.

- Rotary Tool: Lightweight, quiet, easy for beginners to master.

Table: Die Grinder vs Rotary Tool Comparison

|

Feature |

Die Grinder |

Rotary Tool |

|

Size & Weight |

Large, heavy |

Small, lightweight |

|

Power |

High torque |

Moderate power |

|

RPM |

Lower speed but higher strength |

Very high speed, lower torque |

|

Collet Size |

¼ inch |

⅛ inch |

|

Applications |

Grinding, deburring, cutting metal |

Engraving, sanding, polishing |

|

Power Source |

Pneumatic (air) or corded electric |

Corded or cordless electric |

|

User Type |

Professional or industrial |

Hobby, craft, DIY |

Which Tool Should You Choose?

Choose a Die Grinder If:

- You repair cars, weld metal, or work on mechanical projects.

- You need to cut or grind thick metal parts.

- You already have an air compressor setup.

- You value strength and durability over portability.

Choose a Rotary Tool If:

- You enjoy crafting, resin art, or woodworking.

- You want a tool that is easy to hold and light to carry.

- You need to do engraving, sanding, polishing, or detailed drilling.

- You want a versatile all-in-one tool for small DIY projects.

📌Also Read: How to Get Resin Out of Clothes: Tips & Hacks

Conclusion

When comparing die grinder vs rotary tool, it is clear that while they may look similar, they serve very different purposes.

A die grinder is the heavy-duty tool designed for pros in shops and industries. It is powerful enough to grind metal, shape welds, and handle demanding work.

A rotary tool, on the other hand, is the tool of choice for crafters, hobbyists, and anyone who needs precision and detail.

Both are valuable, but your projects will determine which one is right for you. If you need strength and durability, go with the die grinder. If you need control and flexibility for small projects like resin art, jewelry, or engraving, choose a rotary tool.

Explore the best tools and accessories for your projects here:

Make your choice based on your needs. Remember, the right tool makes every job safer, easier, and more enjoyable.

FAQs About Die Grinder vs Rotary Tool

Can you use a rotary tool instead of a die grinder?

Sometimes, for light tasks on soft materials, a rotary tool can stand in for a die grinder. It works for small sanding, polishing, light grinding, and tiny cuts, but it lacks the power and 1/4 inch shank capacity of a true die grinder. Most rotary tools use 1/8 inch bits and higher RPM with less torque, so they are not suited for heavy metal removal or long grinding runs. If you substitute, use the right accessory, keep speeds moderate, apply light pressure, and switch to a die grinder for tough jobs.

Why do they call it a die grinder?

The name comes from tool-and-die work, where machinists used these high-speed grinders to shape and finish dies and molds. The tool’s long, slim body reaches into small cavities and tight corners. Even though many trades use it now, the original name stayed. It still excels at the precise shaping of metal edges and hard materials.

Is a die grinder the same as a cut-off tool?

No. A die grinder is a versatile grinder that uses burrs, stones, and brushes for shaping, smoothing, and deburring. A cut-off tool is mainly for slicing with thin cut-off wheels, often with a right-angle head and guard. Use each tool for its main job to get cleaner results and better safety.

Can they share bits and attachments?

Not usually. Die grinders commonly use 1/4 inch collets, while hobby rotary tools use 1/8 inch shanks. Some adapters exist, but performance and balance are not ideal, and safety can suffer. It is best to use accessories that match the tool’s collet size and speed rating.

Do die grinders only work with air compressors?

Most die grinders are pneumatic, so they run on compressed air. Electric and cordless models do exist, but they are less common and often larger and heavier. If you use air tools, make sure your compressor can deliver the required CFM at the right PSI. Choose the style that fits your workflow and power source.

Are die grinders stronger than rotary tools?

Yes, significantly. Die grinders are built for heavy-duty tasks with more torque and larger shanks, which handle aggressive grinding and metal removal. Rotary tools focus on precision, light sanding, engraving, and small cuts. Pick a die grinder for power jobs and a rotary tool for fine detail work.

Laisser un commentaire

Ce site est protégé par hCaptcha, et la Politique de confidentialité et les Conditions de service de hCaptcha s’appliquent.