How long to cure resin prints is one of the most common questions resin 3D printing enthusiasts ask—and for good reason. Proper curing is what transforms a soft, freshly printed model into a strong, detailed, and durable piece.

Getting the timing right can make or break your final result. Too little curing leaves prints tacky and weak, while too much can cause brittleness or discoloration.

In this guide, we’ll break down the key factors that affect curing time, recommended durations for different resin types, and expert tips to help you achieve a flawless, long-lasting finish every time.

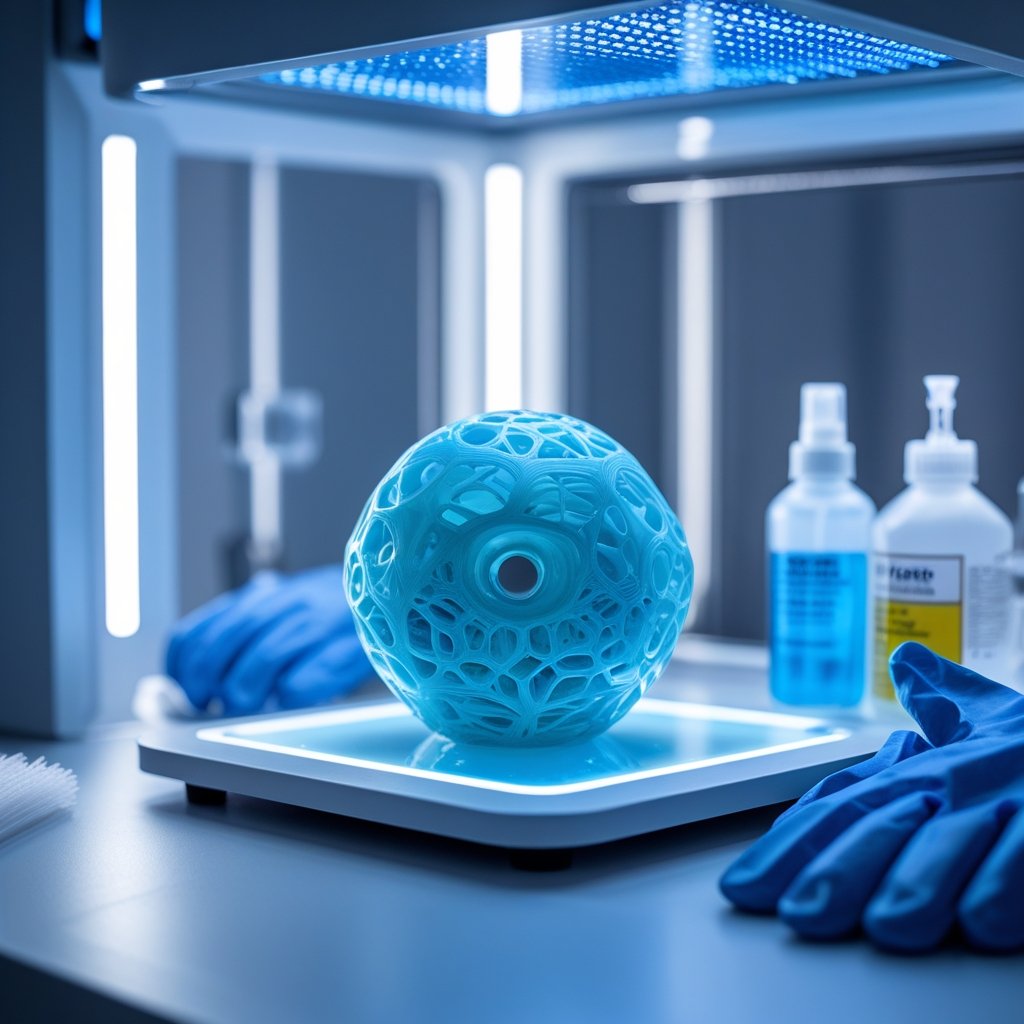

Want faster, more even curing for your resin prints? Explore our range of UV cure boxes designed to deliver professional results every time.

Factors That Affect Resin Print Curing Time

How fast your resin prints cure comes down to several things. The resin itself, print size, UV light strength, and even the room temperature all play a part.

Type of Resin Used

Resins don’t all cure at the same speed. Standard stuff usually cures in 2-4 minutes under UV light. Tougher resins need a bit longer—think 4-6 minutes—because their chemical bonds are stronger.

Clear resins cure quicker than colored ones. Since clear material lets UV light pass through more easily, it hardens up faster. Dark colors like black or red block some of that light and need extra time.

Water-washable resins tend to cure slower than alcohol-based ones—figure about 3-5 minutes versus 2-3 for the regular types.

Flexible resins are the slowest. These soft, bendy materials need 6-8 minutes or more to cure all the way. The chemicals just take longer to harden up.

Plant-based resins cure at average speeds, but they do better if the room’s a bit warmer. Always check your resin bottle for the brand’s recommended times. They’re all a little different.

Layer Thickness and Print Size

Thick layers take longer. A 0.1mm layer cures faster than a 0.3mm one, since the UV light can reach through it more easily.

Bigger prints need more time because there’s just more surface to cover. Small miniatures might be done in 2-3 minutes, but big models could need 5-8.

Complicated shapes with deep grooves or holes need extra attention. The UV light has to reach into all those nooks and crannies. Flat, simple objects usually cure quickly and evenly.

Hollow prints cure faster than solid ones. Less material means less time under the light. Thick, solid walls can block UV rays from reaching the inside.

It helps to turn your prints while curing. Rotate them every minute or two so all sides get their fair share of UV.

UV Light Source and Intensity

How strong your UV lamp is makes a big difference. A 36-watt lamp can cure prints in 2-4 minutes. If you’re using a weaker 9-watt lamp, you might need 8-12 minutes.

LED UV lights are faster than fluorescent tubes. LEDs are more focused, last longer, and just use less power overall.

Distance matters, too. Keep prints about 6-8 inches from the lamp. Too close and you risk hot spots; too far and curing drags on.

More UV lights = faster curing. A chamber with lights on all sides covers everything evenly.

Sunlight does work, but it’s slower—10-15 minutes in direct sun, and up to an hour on cloudy days. Most indoor windows block too much UV for curing.

UV bulbs fade over time. Try to swap them out every 6-12 months if you want consistent results.

Ambient Temperature and Environment

Warmer rooms speed things up. Resin cures best between 70 and 80°F. If your space is under 60°F, the process slows down a lot.

High humidity makes curing drag. Moist air can block UV a bit, so if you live somewhere humid, a dehumidifier might help.

Dust and other particles can get in the way, too. They block UV from hitting the resin’s surface. Try to keep your curing area reasonably clean.

Curing chambers help control temperature better than just leaving prints out. The enclosed space stays warmer from the UV lamps, which helps keep results consistent.

Cold garages or basements in winter make curing take longer. On the flip side, summer heat can make things go too fast. Room temperature is usually the sweet spot.

Recommended Curing Times for Different Resins

Every resin’s a little different, and that affects how long you need to cure it. Standard resins usually need 1-15 minutes, while tough or specialty types can go up to 120 minutes before they’re fully hardened.

Standard Photopolymer Resins

Standard photopolymer resins are what most folks start with. They cure pretty quickly and don’t need anything fancy.

Typical curing times:

- Small prints (miniatures): 1-2 minutes

- Medium prints: 3-5 minutes

- Large prints: 5-15 minutes

Most standard resins use a 405nm wavelength for best results. You can use a curing station or even a UV nail lamp.

Room temperature’s fine for these. Heated chambers aren’t really necessary unless you’re in a hurry.

Keep an eye on your print every few minutes. Properly cured standard resin should feel firm and not sticky at all.

Tough and Flexible Resins

Tough and flexible resins take a lot longer than standard ones. They need more UV energy to reach their full strength.

Extended curing requirements:

- Tough resins: 60 minutes at 60°C

- Flexible resins: 30-45 minutes

- Engineering resins: 60-120 minutes

Adding heat helps these resins cure better. If you can, use a heated chamber for tough resins.

Flexible resins can lose their bendiness if you overdo it. Start with less time, check the flexibility, and only add more if you need to.

If tough resins feel soft or don’t hold details, they’re probably under-cured. Properly cured tough resin should feel solid, but not like it’s going to shatter.

Transparent and Colored Resins

Clear and colored resins behave differently since the amount of light that gets through varies. Clear cures fastest, dark colors need more time.

Color-based timing:

- Clear/transparent: 1-3 minutes

- Light colors: 2-5 minutes

- Dark colors: 5-10 minutes

- Black resins: 8-15 minutes

Dark pigments block UV, so black and deep blue resins can take a lot longer.

If you want a crystal-clear finish, try curing transparent resins underwater. It keeps oxygen from messing with the surface.

Rotate colored prints more often during curing. That way, every side gets the light it needs.

Water-Washable and Eco Resins

Water-washable and eco-friendly resins have their own quirks. They’re safer and easier to clean, but usually need more time to cure.

Eco resin guidelines:

- Water-washable: 15-30 minutes

- Plant-based resins: 20-40 minutes

- Bio-compatible resins: Follow manufacturer specs exactly

Eco resins just take longer, so don’t rush it. Give them the time they need.

Some water-washable resins do better with a two-stage cure: half the time, then rest, then finish curing.

Always check the bottle or manufacturer’s site for specifics on eco resins. They can vary wildly from brand to brand.

Get perfectly mixed resin with zero bubbles. Check out our epoxy resin mixer machines to make your prep process smoother and more consistent.

Tips for Achieving the Perfect Cure

If you want consistent, high-quality results, you’ll need the right gear, a bit of patience, and some attention to detail. The curing method, how you rotate prints, how you control the timing, and a little bit of post-cure testing all make a difference.

Using a Curing Station vs. Natural Sunlight

A dedicated UV curing station really is the best way to go if you want reliable results. They use 405nm UV lights, which match most resins perfectly.

Curing stations can finish miniatures in about 1-2 minutes, and bigger prints in 5-10. You don’t have to worry about clouds or the sun moving around.

Natural sunlight can work, but it’s way slower. Small prints might take 2-3 hours, and big ones could need 10 hours or more of direct sun.

The weather matters a lot. Cloudy days, winter, or early/late sunlight just don’t give you enough UV.

Temperature is a factor, too. Cold days make curing drag on, and really hot surfaces can actually warp your prints if you’re not careful.

UV nail lamps are a decent budget option. They work at similar speeds to curing stations, but sometimes the light isn’t evenly spread out.

If you’re serious about printing, a proper curing station is worth it. It saves time and headaches.

Rotating Prints for Even Exposure

Manual rotation helps all surfaces get the same amount of UV. Give your prints a turn every couple of minutes while curing.

Complex shapes—especially those with deep recesses—need extra attention. Hollow spots or undercuts might not get enough light unless you move them around.

Lots of curing stations have rotating turntables built in. These spin the prints slowly, so you don’t have to do it by hand.

Try to face the thickest parts toward the light first. Dense sections need more UV to get all the way through.

Mix up the angles—put prints on their side, then flip them, so every part gets cured.

Big prints might need partial curing. Cover some areas while you cure others to avoid over-curing thin sections.

Watch out for shadow zones from overhangs or complicated geometry. These spots can stay soft if you don’t reposition the print.

Some folks cure prints underwater to keep oxygen from messing up the surface. It takes longer, but sometimes the finish is a bit nicer.

Avoiding Overcuring and Brittleness

Overcuring makes prints brittle and more likely to crack. Stick to the manufacturer’s guidelines and only add time if you really need to.

Standard resins usually hit their sweet spot in 5-15 minutes in a curing station. Anything past that and you risk making the material too hard or even crumbly.

Dark resins like black or deep blue need more time, while light and clear ones cure quicker thanks to better UV penetration.

Keep an eye out for visual changes—yellowing in clear resin or weird surface textures means you’ve probably gone too far.

Too much heat from long UV sessions can warp your prints. Let thicker parts cool off between curing rounds.

Test with small samples before you commit to a long cure on a big print. That way, you won’t ruin a whole model by accident.

Some brands claim their resins can’t be overcured, but honestly, if you go past 30-60 minutes, even the toughest stuff can get brittle.

Flexible resins are especially touchy. Too much UV and they lose their bendiness fast.

Post-Cure Testing for Strength and Finish

Physical testing helps you check if your print’s really done curing. Just press your fingernail in—if the print’s cured, it won’t dent at all.

The surface tackiness test is handy for spotting undercured spots. A finished print should feel dry, not sticky or gummy.

Detail inspection matters, too. Look for sharp edges and crisp features—if they’re soft or rounded, something’s off with the cure.

Flexibility testing is useful with standard resins. Try gently bending a thin part; it should flex a bit and snap right back, no cracks.

Color consistency can clue you in on even curing. Properly cured prints look uniform—no cloudy patches or weird translucency.

Strength testing means putting a little pressure on joints or thin spots. Well-cured prints won’t snap at the layer lines or supports.

Keep track of your successful settings for next time. Jot down the resin, cure time, and your setup—it’ll save you headaches later.

Progressive testing lets you dial in the perfect cure. Start at the minimum recommended time, then bump it up by a minute or two until you hit that sweet spot for hardness.

Keep your workspace safe and odor-free while curing. Discover our air purifiers for resin built to handle fumes and fine particles effectively.

Conclusion: How Long to Cure Resin Prints

Curing resin prints isn’t just a final step—it’s what gives your creations their strength, clarity, and lasting quality. Taking the time to cure them properly ensures your prints look great and hold up over time.

Remember, factors like resin type, UV intensity, and print size all play a role in how long to cure resin prints. A little patience goes a long way toward achieving professional results.

Ready to put your cured prints to good use? Check out our guide on creating stunning resin home décor for your next creative project.

Frequently Asked Questions

Here are some of the questions people ask most about curing resin prints. You’ll get tips on spotting a fully cured print and a sense of how long different methods actually take.

How do I know if my resin print is cured?

A fully cured resin print has a smooth or matte finish and feels solid with no flex. Tap it on a hard surface—if it’s done, it’ll sound crisp and stone-like. Under-cured prints feel sticky or damp, while over-cured ones turn brittle and may yellow.

Can resin cure in 2 hours?

Two hours isn’t enough for a full cure with standard methods. UV curing stations finish most prints in 1–10 minutes, depending on size. Sunlight takes longer—small prints may need 2–3 hours, large ones up to 10.

How long does it take to cure resin with UV light?

Small prints cure in 1–2 minutes under UV light, medium ones in 3–5, and large ones in 5–10. Timing depends on resin type and thickness. Start short, then extend if needed—UV curing is faster and more consistent than sunlight.

Are resin prints safe after curing?

Fully cured prints are safe to handle since the resin becomes solid plastic. Uncured residue, however, can still irritate skin. Always wash prints with isopropyl alcohol before curing, and remember—only food-safe resins are suitable for items that contact food.

اترك تعليقًا

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.