Resiners® 1 gallon/2 gallon Crystal Clear Epoxy Resin with Tailored Diversion Port

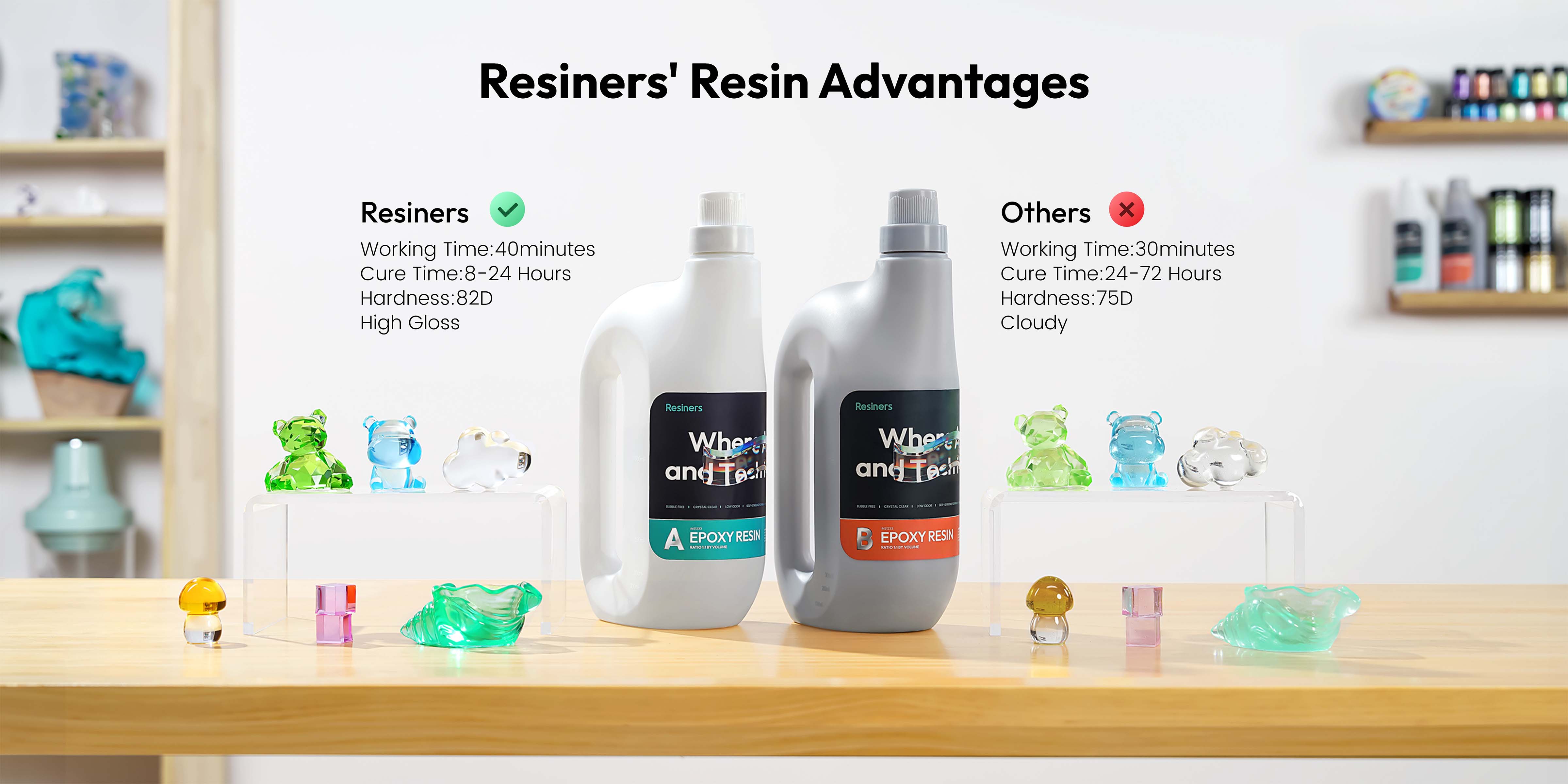

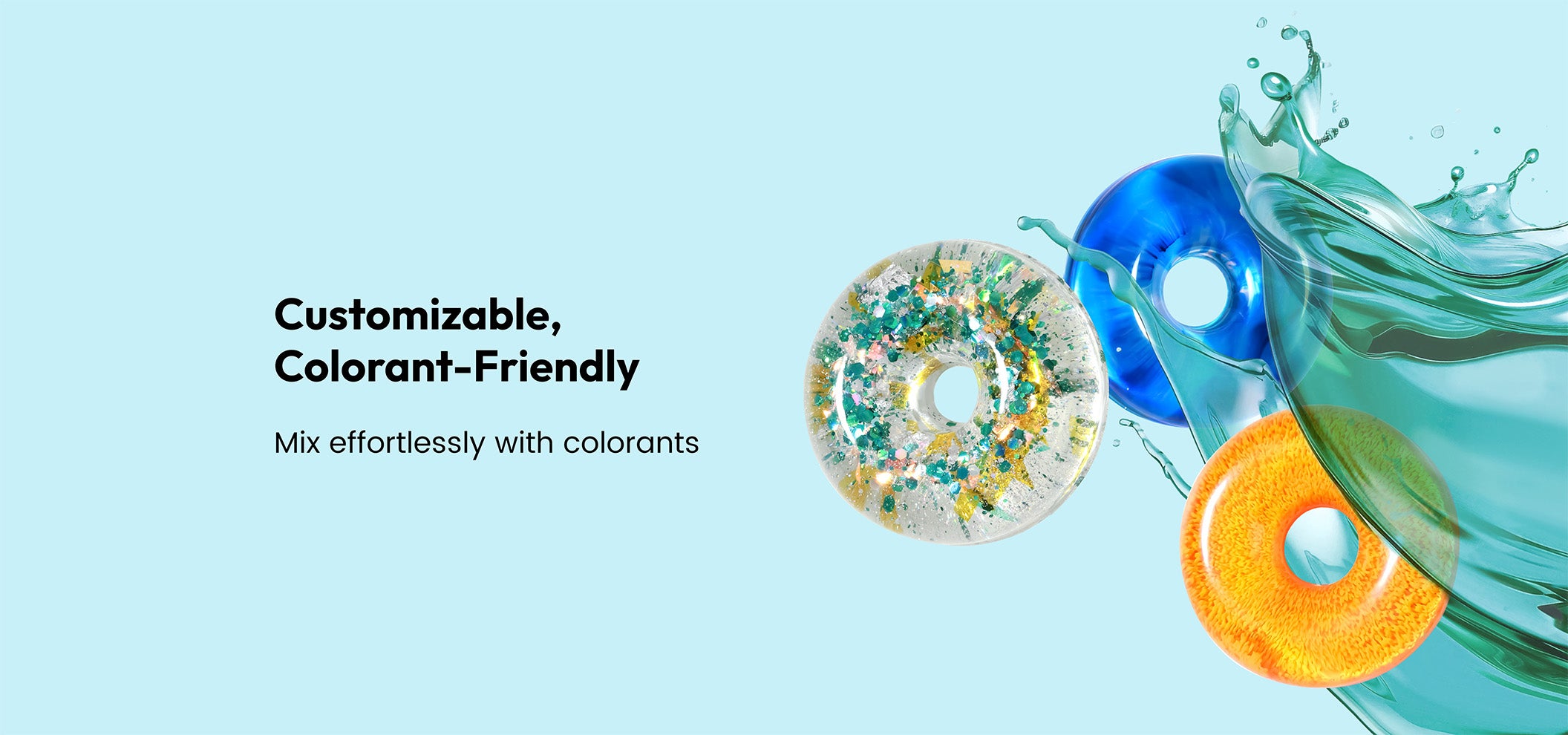

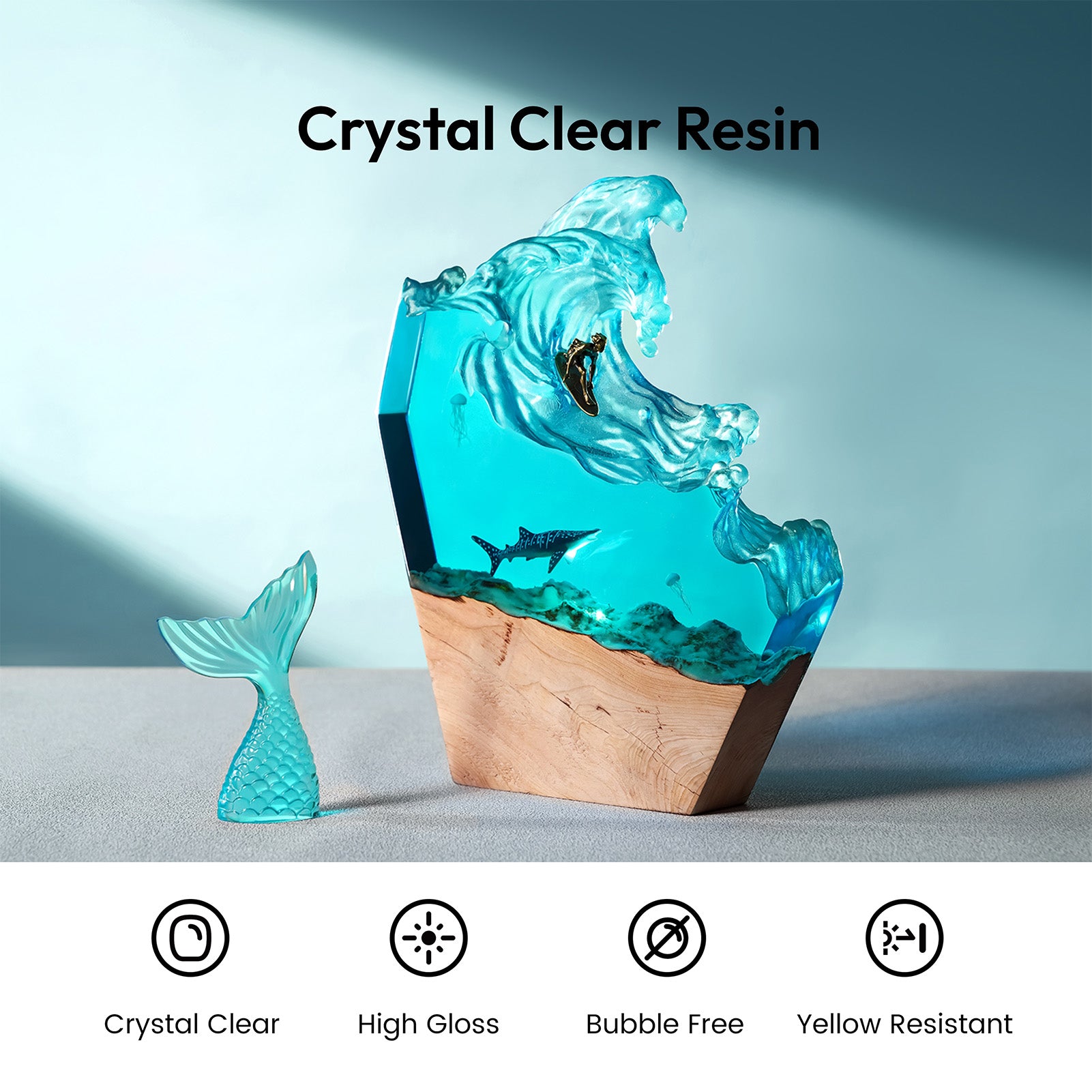

- High gloss & Top-Quality - Using a bubble-free ingredient formula (Resin A & B mixtures: epoxy resin, benzyl alcohol, amino-terminated polyoxypropylene, polyether modified polydimethy siloxane, yellow inhibitor HN-150), Resiners epoxy resin offers high transparency, creating an anti-foaming, crystal clear, glass-like finish to enhance the beauty of the final product, and high gloss, giving finished projects a professional, polished appearance.

- No more resin spilling & Better control of pouring - The innovative diversion port design prevents resin spills during pouring, enabling easier and more precise control for enhanced resin artwork. Additionally, the specialized port design prevents adhesive caps from sticking to the nozzle, simplifying the removal process.

- Low Odor &Suitable for Indoor and Outdoor Use - Formulated for a more enjoyable crafting experience, this epoxy resin features a clean, low-odor profile that makes it perfect for both indoor and outdoor applications. Whether you're working in a studio or open space, it supports a more comfortable environment—without the overwhelming smells often associated with resin work.

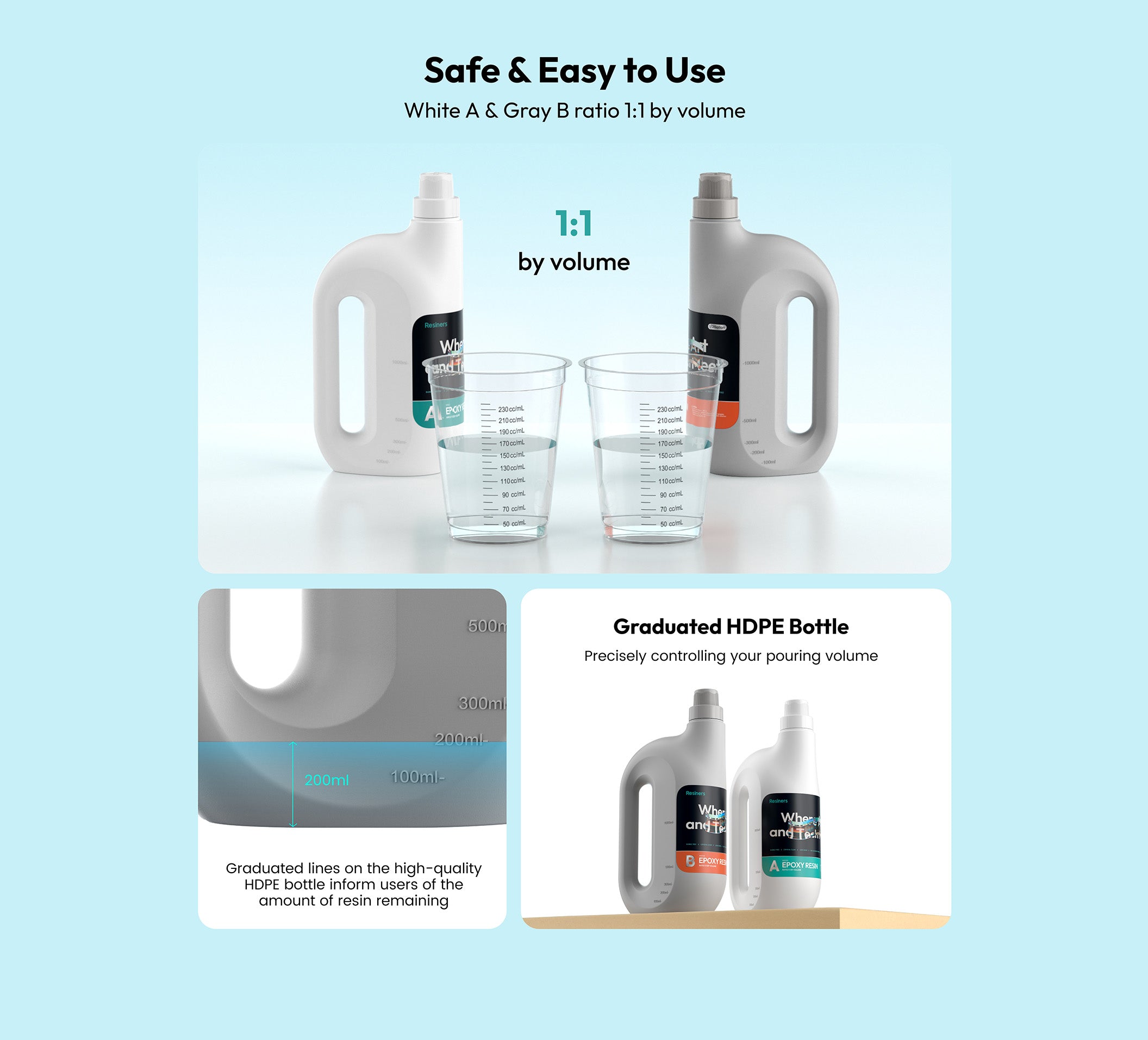

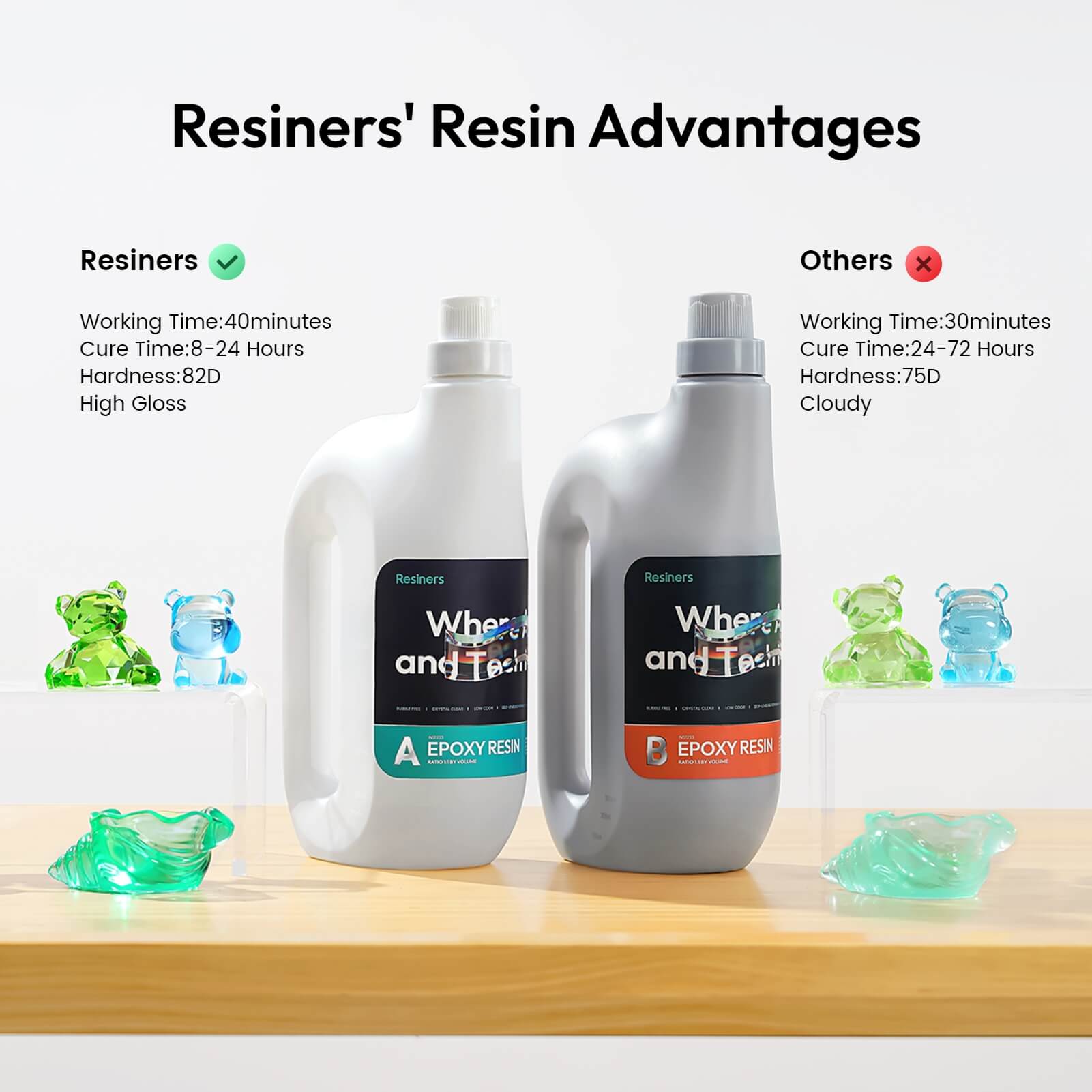

- Safe & Easy to Use - White A & Gray B ratio 1:1 by volume. The Resiners’ epoxy system features a convenient color-coded design with the A resin bottle in white and the B hardener bottle in gray. This color distinction makes it easy to differentiate between the two bottles and ensures an accurate 1:1 volume ratio when combined.

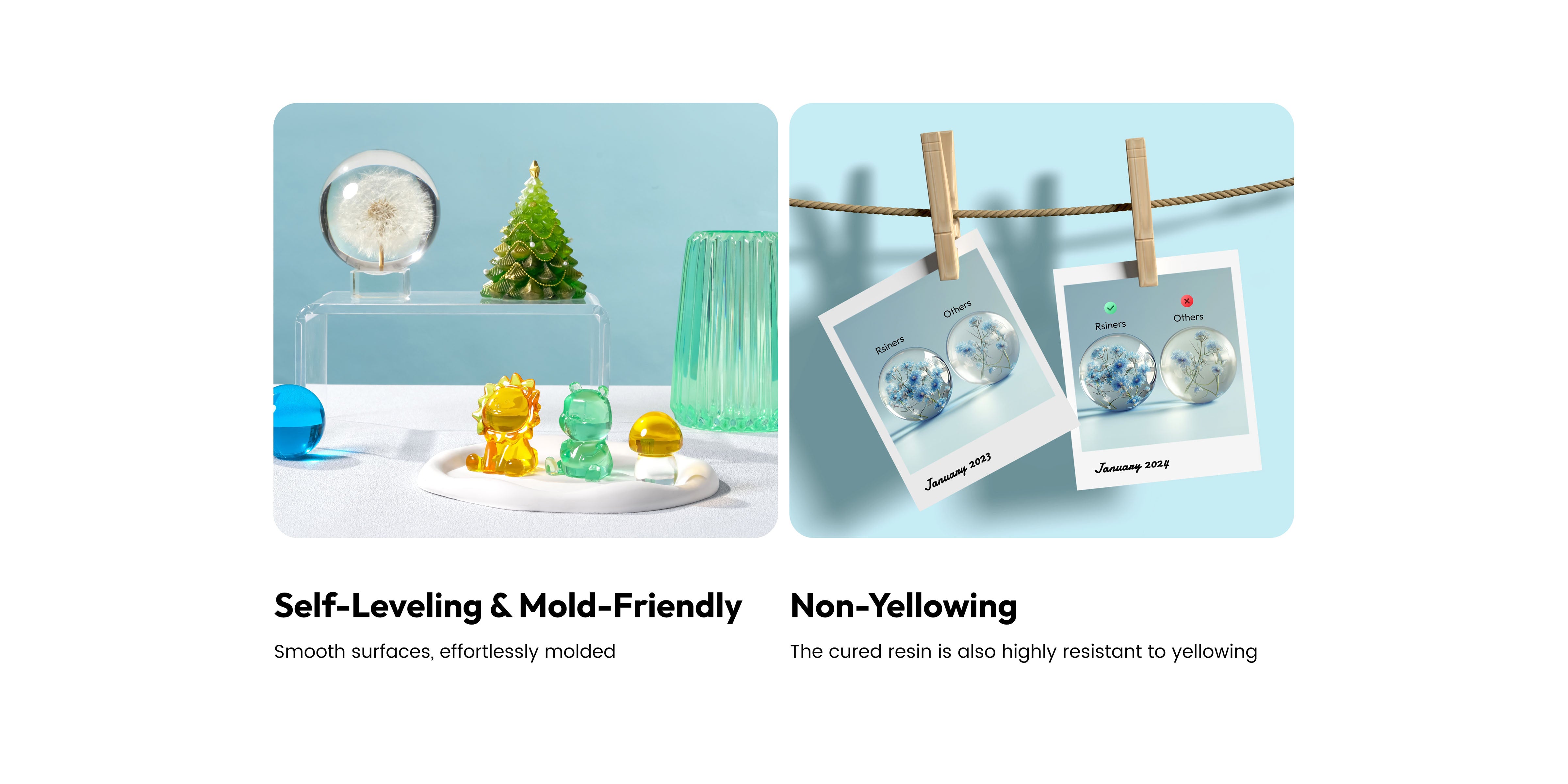

- Fast Cure in 8 Hours & Non-Yellowing - Effortless excellence, rapid cure, enduring quality, while heat dissipation is not too high to damage molds. The resin can be demolded after 8 hours (77℉-85℉) and fully cured in 24 hours, and with Resiners resin-curing machines, the waiting time can be reduced to even 2 hours, greatly increasing the efficiency of project completion. The cured resin is also highly resistant to yellowing, ensuring long-lasting clarity and transparency with durable performance.

- Ergonomic Bottle Design - Easy-to-hold streamlined bottle body. The resin is packaged in a streamlined and sealed bottle that makes it easy to grip and handle during application while maintaining its freshness and preventing air or moisture from affecting its quality.

- Graduated HDPE Bottle - Precisely controlling your pouring volume. Graduated lines on the high-quality HDPE bottle inform users of the amount of resin remaining, eliminating doubt as to whether it is enough for their artwork and whether a new bottle is needed. It can also minimize spills for improved pouring perfection.

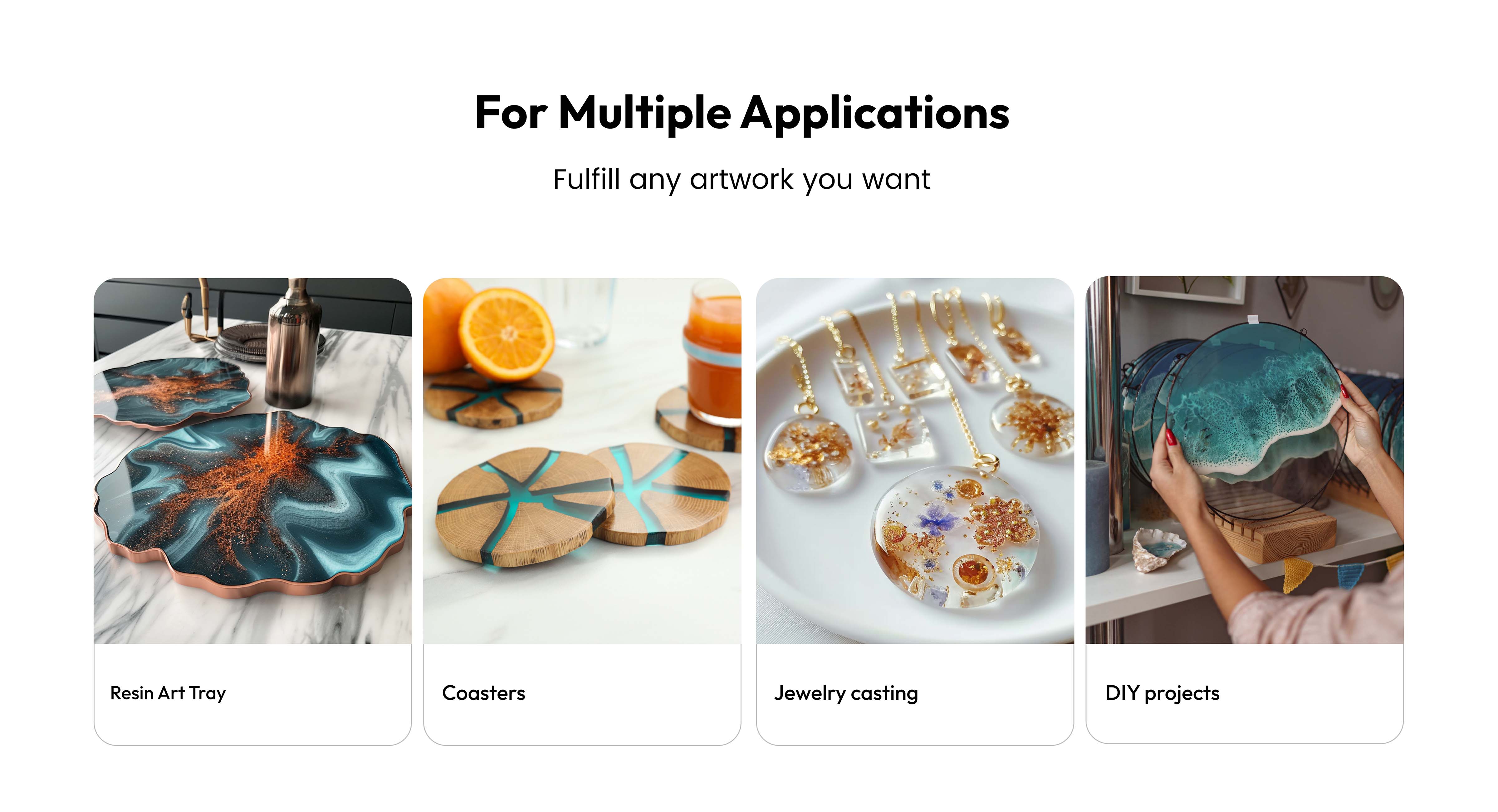

- For Multiple Applications - Fulfill any artwork you want. Resiners epoxy resin unleashes creativity for a variety of art crafts. You can use it to do DIY resin projects like jewelry casting, table-top or bar-top casting, resin coasters, molds, petri dish art, acrylic paint pouring art, and more. Unlock endless possibilities for artistic expression.

Tips: Due to shipping restrictions, our 1gallon epoxy resin can only be shipped to the US.

FAQ

How to avoid bubbles in Epoxy?

1. Mix slowly but longer to avoid incorporating air while mixing manually.

2. While mixing big quantities using a mixing tool, make sure you don’t create a “VORTEX” by mixing too fast.

3. Use a bubble removal machine to remove bubbles.

4. Pouring from a corner with a small stream will help the epoxy travel and eliminate bubbles when failing.

Why is Temperature Crucial When Working with Epoxy Resin?

The temperature of the environment and materials can affect the behavior of epoxy resin. The temperature can impact the following aspects of working with epoxy resin:

Viscosity: Viscosity is the thickness or flow of the resin. Epoxy resin becomes more viscous in colder temperatures, making it harder to mix and work with.

Curing Time: The curing time of epoxy resin depends on the temperature. Higher temperatures can speed up the curing process, while colder temperatures can slow it down.

Strength: Temperature can affect the strength and durability of epoxy resin. Optimal temperature conditions can ensure that the resin cures properly and achieves maximum strength.

The Ideal Temperature Range for Epoxy Resin Work

The ideal temperature to work with epoxy resin is between 70-74°F (20-24°C). This temperature range allows the epoxy to flow easily, while also ensuring proper curing.

If the temperature is lower than 70°F (20°C), the epoxy may become too thick and difficult to work with, and if it is higher than 75°F (25°C), the curing process may be accelerated, making it harder to achieve a smooth finish and can possibly overheat.

Can I use a heat lamp to speed up the curing process of epoxy resin?

Using a heat lamp to speed up the curing process of epoxy resin is not recommended

as it can cause the resin to cure too quickly and potentially lead to cracks.

Will All Epoxy Resin Turn Yellow?

Yes, all epoxy resin will yellow over time.

However, some will have better resistance than others and can take up to several years before any noticeable change in color occurs.

How do you keep resin clean?

For the purists who like to keep it simple, here's what you need: wax paper, dish soap, and paper towels. Lay down the wax paper (think of it as your cleaning canvas), and while your resin is in its early curing stages, scrape off as much as you can. A little warm water and soap action, and you're golden!

How do I calculate the amount of resin needed for a project?

Measure the Perfect Amount for Your Project>>>Epoxy Resin Calculator