Learning how to mix epoxy correctly is easier than you might think! When done right, your epoxy will cure into a strong, crystal-clear finish that's perfect for crafts, repairs, or coating surfaces.

The secret is all in the mixing—combining the resin and hardener at the exact ratio on the package and stirring thoroughly for at least 2-3 minutes. Don't eyeball it or rush the mixing, or you'll end up with sticky spots that never harden!

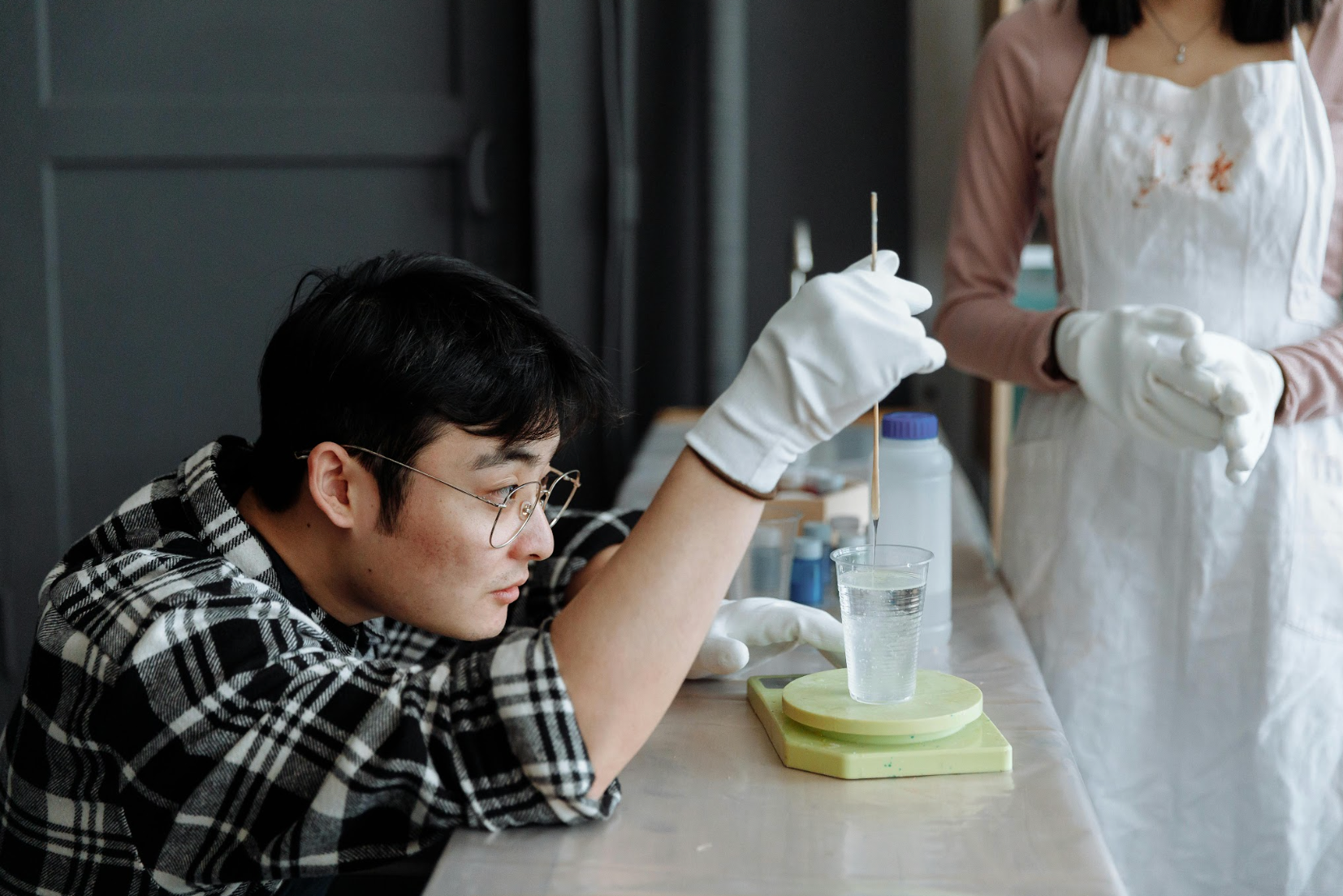

Always wear gloves to protect your skin, and don't worry about fancy equipment. Even cardboard works great as a mixing surface. Ready to become an epoxy pro? Keep reading for all the details!

How To Mix Epoxy: Step-By-Step Guide

Mixing epoxy properly is super important for your project's success. Let's walk through the steps to get it right!

Step 1: Gather your supplies

- Epoxy resin and hardener

- Clean mixing containers

- Stirring sticks

- Measuring tools

- Gloves and safety glasses

- Well-ventilated workspace

Step 2: Measure carefully

Most epoxy requires a 2:1 ratio (2 parts resin to 1 part hardener) by volume. Some brands might need different ratios, so always check the package instructions.

Step 3: Pour and combine

Pour the resin first, then add the hardener. Be exact with measurements! Even small mistakes can ruin your mix.

Step 4: Stir thoroughly

Mix slowly to avoid creating bubbles. Stir for about 4-5 minutes to make sure everything is well combined.

Scrape the sides and bottom of your container while mixing.

Step 5: Safety first!

Always wear gloves to keep wet epoxy off your skin. Work in a ventilated area and consider wearing a mask too.

If you need to add color or fillers, mix them in after the epoxy is fully combined. Pour your mixed epoxy quickly since it will start to harden.

Remember that temperature affects how fast epoxy cures. Warmer rooms speed up the process, while cooler spaces slow it down.

Expand your knowledge by reading our article Epoxy Resin for Beginners: Essential Starter Guide to take your crafting skills to the next level.

Epoxy Basics You Need To Know

Working with epoxy means understanding a few key principles. Getting the mix right and knowing what materials you're working with can make or break your project.

Epoxy Components and Mixing Ratios

Epoxy consists of two parts: resin and hardener. When you mix these together, a chemical reaction starts that turns the liquid into a solid.

You must follow the exact mix ratio on your product label. Some epoxies use a 1:1 ratio, while others might need 2:1 or 3:1.

Measuring by weight is often more accurate than measuring by volume. A digital scale helps you get the perfect mix.

For example, if your epoxy has a 2:1 ratio by weight, you'd use 100 grams of resin with 50 grams of hardener.

Always wear gloves when mixing epoxy! The chemicals can irritate your skin. Mix thoroughly for at least 3-5 minutes, scraping the sides and bottom of your container.

Temperature matters too. Most epoxies work best at 70-75°F (21-24°C). If it's too cold, your epoxy might not cure properly.

Understanding how to mix epoxy is essential, but knowing which resin to choose is equally important. Explore Types of Resin: A Crafter's Guide to Finding the Perfect Pour to match the right resin to your project needs.

Safety Precautions for Mixing Epoxy

Working with epoxy requires careful attention to safety. Protecting yourself from harmful chemicals and setting up a proper workspace are essential steps before you start mixing.

Required Protection and Workspace Setup

Always wear protective gloves when handling epoxy resin and hardener. These chemicals can cause skin irritation and allergic reactions.

Nitrile gloves work better than latex for this job. Protect your eyes with safety goggles.

Splashes happen even when you're careful! Wear old clothes or an apron that covers your arms. Epoxy is nearly impossible to remove from fabric once it sticks.

Make sure your workspace is well-ventilated. Open windows or use fans to keep fresh air flowing.

Breathing epoxy fumes can make you sick. Cover your work surface with plastic sheeting or wax paper. This makes cleanup easier and protects your table.

Keep your mixing area away from food, pets, and children. Never use kitchen containers for mixing epoxy—use plastic or metal containers specifically for this purpose.

Work in a room with good lighting so you can see what you're doing and avoid spills.

Tools and Materials Needed

Before you start mixing epoxy, gather everything you'll need. Having the right tools will make your project go smoothly and help you get better results.

Measuring and Mixing Equipment

You'll need clear measuring cups with volume markings for accurate measurement. Plastic cups work well, but make sure they're clean and dry.

Look for cups that show ounces or milliliters clearly. Stirring sticks are super important! Wooden craft sticks or plastic mixing sticks work great.

Don't use your good kitchen utensils - epoxy is tough to remove. A mixing container is also needed. Pick one that's wider than it is tall to make stirring easier.

Some folks like using plastic containers with flat bottoms. Don't forget gloves to protect your hands! Nitrile gloves work better than latex with epoxy.

Also grab some paper towels for quick cleanups. If you're working with West System epoxy, they sell special pumps that measure the right ratio automatically. These pumps can save you time and reduce mistakes. A timer helps you track mixing time.

Most epoxies need 2-4 minutes of thorough mixing.

The Epoxy Mixing Process

Mixing epoxy correctly is crucial for a successful project. When you follow the right steps and techniques, you'll get strong, clear results without sticky spots or unwanted bubbles.

Accurate Measurement Techniques

Start by gathering your supplies: clean mixing containers, measuring cups, and stir sticks. Always wear gloves to protect your skin from the chemicals.

Read the instructions on your epoxy package carefully. Different brands have different mix ratios.

Most epoxies use a 1:1 or 2:1 ratio of resin to hardener. This ratio is super important!

If you get it wrong, your epoxy might:

- Stay sticky and never harden

- Turn yellow faster

- Be weaker than it should be

For small projects, use cups with measurement lines. For bigger jobs, a digital scale works better.

Pour each part separately and check the amounts twice before mixing.

Proper Mixing Methods and Duration

Once you've measured correctly, it's time to mix! Use a flat stir stick to combine the resin and hardener.

Stir slowly at first to avoid trapping air bubbles. Scrape the sides and bottom of your container while mixing.

You need to mix for at least 2-3 minutes. This isn't just stirring - it's helping a chemical reaction happen!

Look for these signs of good mixing:

- No streaks or swirls

- Even, clear appearance

- Consistent thickness

Some tips for better results:

- Mix in a warm room (70-75°F is perfect)

- Use the right container size - not too wide or too deep

- Pour into a new container and mix again for extra-clear results

If you see lots of bubbles, let the mix sit for a few minutes before pouring. You can also use a heat gun lightly over the surface.

Mastering how to mix epoxy is just the first step—you'll need the perfect shape for your project. Check out our epoxy mold collection to find the ideal vessels for your properly mixed resin.

Common Mixing Problems

Even the most careful epoxy enthusiasts face mixing challenges. Being aware of these issues can help you achieve better results and avoid wasting materials.

Fixing Bubbles, Cloudiness, and Curing Issues

Bubbles are a frequent problem when mixing epoxy. They form when you stir too quickly or vigorously.

Mix slowly and thoroughly to prevent air from getting trapped. If bubbles appear, you can use a heat gun or torch held about 6-8 inches away to pop them.

Cloudiness usually happens when you don't mix the resin and hardener properly. Always use the two-cup mixing method to ensure thorough blending.

Mix in one cup first for about 2 minutes, then pour into a second clean cup and mix again. This helps create a uniform mixture without streaks.

Curing issues often result from incorrect ratios. Make sure you measure exactly as directed on the package.

Too much or too little hardener will prevent proper curing, leaving your project sticky or flexible instead of hard. Room temperature also matters! Epoxy cures best between 70-75°F.

If your epoxy stays soft after curing, it's usually because the components weren't mixed well enough. Remember that thorough mixing is key to chemical reactions that create hardness.

Working With Mixed Epoxy

Once you've mixed your epoxy properly, knowing how to work with it efficiently is crucial. Timing and proper handling will make the difference between a successful project and a sticky mess.

Understanding Pot Life and Application Timing

Epoxy mixtures have a limited working time called "pot life." This is how long the epoxy stays workable before it starts hardening.

Most epoxies give you between 20-40 minutes of working time. The clock starts ticking as soon as you mix!

Temperature affects pot life significantly. Warmer rooms make epoxy cure faster, while cooler spaces slow it down.

If you're working with fiberglass, spread the epoxy quickly after mixing to get the most working time.

Watch for signs that your epoxy is starting to thicken. When it gets harder to spread, stop working with that batch.

Trying to use partially cured epoxy leads to weak bonds and poor finish. For larger projects, mix smaller batches. This gives you fresh epoxy throughout your work session.

Cleanup and Storage

Clean your tools right away before epoxy hardens! Use rubbing alcohol, acetone, or vinegar on metal tools. Don't wait until later—cured epoxy is super hard to remove.

For your skin, use waterless hand cleaner or citrus-based cleaner. Avoid harsh solvents on your skin as they can cause irritation.

Store unused resin and hardener in separate, sealed containers. Keep them in a cool, dry place away from direct sunlight.

Most epoxy components have a shelf life of 6-12 months. Dispose of cured epoxy with regular trash. However, liquid epoxy is hazardous waste and needs special disposal.

Check your local regulations for proper disposal methods. Label your storage containers with dates so you know how fresh they are.

With your epoxy mixing skills locked down, it's time to put them to creative use. Read our article, Unique Resin Art Ideas: Creative Projects for Every Creator for inspiration on what to make with your perfectly mixed epoxy.

Advanced Mixing Tips for Epoxy

When adding colorants to epoxy, start with just a tiny amount. Too much color can prevent proper curing.

Mix the colorant into one part (usually the resin) before adding the hardener. This helps avoid streaks in your final piece.

Temperature affects epoxy's viscosity a lot. Cold epoxy can be thick (high cps) and hard to mix. Warm your resin and hardener to about 75°F before mixing for the best results. You can place bottles in warm water for 10-15 minutes.

In humid conditions, work quickly and mix thoroughly. Humidity can cause cloudiness or bubbles. Try to work in a space with less than 50% humidity when possible.

Pro tip: For thick epoxy (high viscosity), use a folding method. Move your mixing stick in figure-eight patterns while scraping the sides and bottom of your container. This captures unmixed material without trapping air bubbles.

For very detailed projects, strain your mixed epoxy through a fine mesh to remove tiny unmixed particles. This extra step is worth it for crystal-clear results!

Properly mixing epoxy helps prevent air bubbles, but sometimes they still appear. Find out why in our detailed article: Why Are There Air Bubbles In My Resin Project? for bubble-free results every time.

Final Thoughts

Now you know how to mix epoxy like a pro! Remember, the perfect mix comes down to exact measurements and thorough stirring - no shortcuts! With these simple steps, you'll avoid sticky messes and create strong, clear results every time.

Don't forget your gloves and take your time during the mixing process. Whether you're making jewelry, sealing a table, or fixing something around the house, proper epoxy mixing makes all the difference. Give it a try on your next project, and you'll be amazed at how professional your results can look.

Now that you know how to mix epoxy perfectly, add vibrant colors to your creations. Check out our epoxy resin dye collection to transform your perfectly mixed epoxy into stunning colorful masterpieces.

Ready to take your epoxy skills to the next level? Also check out our article on How to Dye Epoxy Resin for colorful project ideas!

Frequently Asked Questions

Does epoxy mix with water?

No, epoxy does not mix with water. Epoxy is water-resistant by nature. If you add water to epoxy, it will not blend properly. The water will create bubbles and weak spots in your final product.

Water can also mess up the chemical reaction needed for epoxy to harden. Keep your mixing area and tools completely dry when working with epoxy.

Will epoxy still cure if it gets wet?

Most epoxies won't cure properly if they get wet during the curing process. Water interferes with the chemical reaction between the resin and hardener.

If your epoxy project gets wet before it's fully cured, you might see cloudiness, soft spots, or a sticky surface.

Some specialty marine epoxies can cure underwater, but regular epoxy needs a dry environment.

What happens if you mix epoxy wrong?

Mixing epoxy incorrectly can cause big problems. If you don't use the right ratio of resin to hardener, your epoxy might stay sticky or soft forever.

Poor mixing technique can also create streaks or uneven spots. If you don't mix thoroughly enough, parts of your project might never fully harden.

Always follow the exact ratio on the package and mix very well.

What is the formula for epoxy?

The typical formula for epoxy is a 1:1 or 2:1 ratio of resin to hardener by volume. This means equal parts or twice as much resin as hardener.

Different brands have different formulas. Some specialty epoxies use different ratios.

Always check your specific product instructions. Don't guess or estimate—measure carefully for best results.

What kind of container is recommended for mixing epoxy?

Plastic mixing cups with measurement markings work best for mixing epoxy. Look for cups made of polypropylene (often marked as #5 plastic). These won't react with the epoxy chemicals. Avoid paper cups, as they can contain moisture.

Don't use foam cups either - epoxy can melt them! Metal containers can work but might be harder to clean. Always use a container bigger than you think you need to prevent spills when mixing.

اترك تعليقًا

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.